Your tyres are a mixture of rubber and steel that keep your car or motorbike from sliding off the road. On a car, they control 1500kg of metal on four contact patches, each about as big as your hand; on a motorbike, it’s just two contact patches, each the size of a credit card.

With the extreme forces we put our tyres under we need to keep them in good condition: correct inflation, adequate tread depth and correct alignment. Let’s look in more detail at the factors that affect your vehicle’s performance, and how to look after your tyres.

Inflation

The air in your tyres is under pressure so that the tyres can support the weight of the vehicle and resist cornering forces. If the tyres are cold, the pressure is slightly less than when they’re warm because hot air expands. However, the tyres will operate fine within a range of several PSI (pounds per square inch).

Manufacturers give a recommended pressure for each vehicle. Even though you might buy the same brand and size of tyre as your friend has on a different vehicle, it’s the weight of your vehicle that influences what pressure should be put in the tyre.

If you change your wheels to bigger wheels, for example, you move from 16-inch alloys to 17-inch alloys, the pressure will be different.

The trade-off

The flatter the tyre, the more of it that is in contact with the road, therefore there’s theoretically more grip. However, a flatter tyre flexes more in the sidewall (the side of the tyre) and the tread, and the tread blocks move around more. The increased surface in contact with the road, plus the increased sidewall flex and tread movement heats up the tyre more. There’s more rolling resistance; it takes more energy to get the tyre rolling and to keep it rolling, therefore fuel economy suffers. If the cornering forces are enough and the tyre is flat enough, there’s a risk it can come off the rim.

This extra heat can give more grip to the tyre, but only up to a point as excessive heat will cause the tyre to blister or delaminate in extreme circumstances.

Conversely, if you pump up your tyres really hard, there’s less of the tyre in contact with the road. This means less rolling resistance – it takes less fuel to keep your vehicle moving. However, it also means less grip. When your tyres are really hard your steering will feel light. The tyres are also part of the ‘unsprung mass’ of the vehicle, and they actually act as part of the suspension system, absorbing vibrations and bumps from the road. If they’re too hard, you will feel that the vehicle is bumpier, and it may not ride as well.

The recommended tyre pressure has been tested to be the best compromise for all the above situations.

Deviations from the recommended pressure

If you are carrying a heavy load then you should put more air in your tyres.

If you get stuck in soft mud or sand, a way of getting out is to let some pressure out of your tyres. This will allow more of the tyre in contact with the surface and will give you more grip.

A tyre will have the maximum load in pounds and kilograms that the tyre can support when properly inflated printed on the sidewall.

Tread depth

Tread depth is most important for wet roads. The legal minimum tread depth is 1.6mm for a car, or 1mm for a bus or truck, however, the wet weather performance of a tyre drops off dramatically once the tread depth is less than 3mm.

On wet roads the tread allows water to be dispersed. If it wasn’t there, the tyre would ride up on top of a pressure wave of water. This is called aquaplaning. When you have brand new tyres, they have deep treads and have the capacity to disperse a lot of water, but they have worse grip on dry roads at the limit because the tread blocks are taller and therefore more around more.

Racing cars have slick tyres for dry weather – these are tyres with no tread. However, they’re a different compound to road tyres (which we’ll get to in a minute). They’re much softer.

If you’re thinking that you should wear your road tyres down until they’re almost bald, think again. The rubber compound used for road tyres is not particularly grippy once your tyres are quite bald. Slick tyres work by exchanging a layer of rubber with the tarmac, and therefore have a lot of grip (once they’re up to operating temperature), but wear out very quickly; road tyres don’t do this.

Checking treads

In day-to-day driving your tyres will pick up debris, such as stones, glass and, if you’re unlucky, a nail or other item that can puncture your tyre. If you leave a stone or sharp object lodged in the tread, over a period of time it will wear away at the rubber and can eventually cause either a weak spot, or a puncture. Check your treads periodically. If you notice an unusual vibration or noise that seems to be coming from a tyre, you might have picked up a stone or a nail. A slow puncture from a nail can usually be repaired if you don’t drive on it for too long.

Tyre compound and construction

Almost all tyres used now are steel-belted radial tyres, and this is denoted by the R in the tyre measurement, e.g. 235/45ZR17. The Z in this case means the tyre is rated above 300kph. Radial means that there are radial ply cords (layers of fabric making up the body of the tyre) running between the sidewalls.

Treadwear, which is how fast the tyre’s tread wears out, is often indicated by a number on the sidewall which is a comparison to a standard Course Monitoring Tyre. The Course Monitoring Tyre has a rating of 100. If your tyre has a rating of 300 then it can be expected to last roughly three times as long as a Course Monitoring Tyre.

The softer the tyre the more grip it will have, but it will wear out quicker.

Tyre type

As well as your common or garden standard tyres there are also reinforced ones that are usually seen on vans and light trucks, but also on some SUVs and caravans. Some tyres are specialised for mud or snow and will have M or S marked on the sidewall.

Width

The width of a tyre is measured in millimetres from sidewall to sidewall. If your tyre’s dimension is 225/60R16, as in this image, then the tyre is 225mm wide and fitted to a 16-inch rim. Theoretically, the wider the tyre, the more grip because there’s more tyre in contact with the road. However, wider tyres distribute the pressure of the vehicle over a broader area, so this doesn’t work exactly in proportion. I.e. if you double the width of a tyre it doesn’t double the contact patch on the road.

It’s true that wider tyres will give better performance, but only to a point. Vehicles are engineered to fit a certain type of tyre, and it’s often limited by the width of the wheel arches. If the tyres are too wide, the vehicle will want to follow every minor deviation in the road surface (this is called tramlining), and it will be challenging to drive. If you drive on tyres that are too narrow, the weight of the vehicle will mean that cornering and braking performance is less.

Rotating the wheels

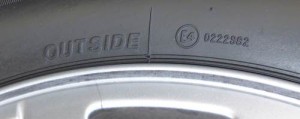

To ensure even wear on your tyres you can ‘rotate’ them which, in this case, means putting the front tyre on the rear and the rear tyre on the front. If your tyres are unidirectional, don’t swap the sides of the tyres. These are tyres that only disperse water well in one direction. If you swap a unidirectional tyre from the left to the right or vice versa, you increase your risk of aquaplaning in the wet.

This is mostly impossible on a motorbike as, even if the wheels were the same size, you would need to remove the tyre from the rim to swap them.

Wheel alignment

The wheel alignment, or tracking, is the angle of the wheels in relation to the vehicle. Each manufacturer provides its own specifications. If the tyres fall out of alignment then they will wear unevenly and prematurely. Misaligned wheels also waste fuel.

The wheels can be aligned in three ways at the front: caster, camber and toe (camber is often called rake and trail on a motorbike); and two ways at the rear (camber and toe).

A small amount of camber can assist with cornering, but large amounts of camber often seen in ‘flush fitments’ wear tyres prematurely and reduce straight-line braking performance.