Some lorries have auxiliary equipment which requires power, but they don’t have a PTO or power take-off that draws power from idling the main engine. Instead, they have a small auxiliary engine which can provide the power.

Common applications for this include chillers on refrigerated trailers, the cranes on side-loader trailers and air compressors on vehicle service trucks. For this reason, it’s important that the engines are reliable otherwise downtime causes lost revenue.

Auxiliary engines are serviced based on the number of hours they are run, compared to the lorry itself which will be serviced based on mileage.

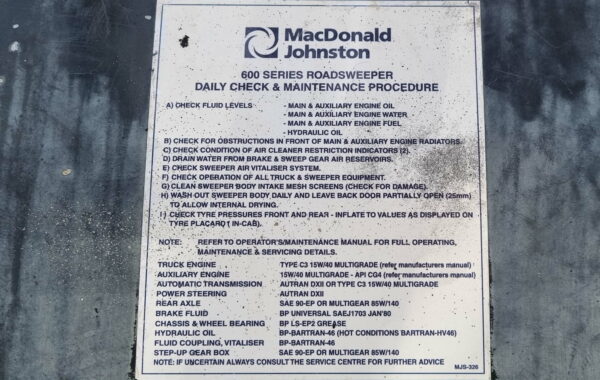

Instructions for operation are often shown on a decal

Auxiliary engines and connecting components need to be checked as part of the regular pre-start inspection. However, they can often be tucked away out of sight, so it’s important that if a new driver is using the lorry that they are shown where the engine is and how to stop and start it. Sometimes it’s right between the chassis rails, sometimes it’s behind a panel, sometimes you need to tip the cab, and sometimes it’s easily accessible near other components such as the toolbox.

There may be information about what to check before operating the engine, and what type of fluids to use.

If there’s no instructions for the pre-start check for the auxiliary engine, it should include:

- Ensuring the battery terminals are clean and tight, and that the battery is secured

- Checking the fuel tank isn’t damaged or leaking

- Checking that the fuel isn’t contaminated, there’s no sediment and that there’s sufficient for the requirements

- Examining hydraulic hoses and other connections for leaks

- Maintaining the engine oil and coolant at the correct level

- Checking the fan belt tension and wear

- Removing any obstructions from the radiator and checking there’s no damage

- Logging a service request if the hours meter shows that it’s due.

Using good quality fuel and oil will help keep the auxiliary engine running smoothly.