When you’re driving a vehicle that’s several times heavier than your average car, you need to know how to look after your brakes and how to use them properly. This article covers all the knowledge you’ll need for your theory test for heavy vehicles and passenger carrying vehicles.

Jake brakes, exhaust brakes and retarders

While the service brake is the most powerful brake on a bus or lorry, other braking systems are used because service breaks are friction-based and can overheat quickly on long declines. Well-maintained service brakes will provide even, powerful, consistent braking on all wheels. They are the brakes you will use the most in general driving.

The three main braking systems are called service brakes, secondary brakes and parking brakes. The service brake performs the primary function of stopping the vehicle when you depress the footbrake. The secondary brake system is for use in the event of failure of the service brake. The parking brake should normally only be used when the vehicle is stationary, including if you are making a short stop facing uphill.

A Jake brake is an additional method of slowing a vehicle down. It works by altering the valve timing in the engine. It’s a genericised trademark of Jacbos brake which is a compression release engine brake.

Jake brakes are noisy, so avoid using them in urban areas.

A system for controlling the vehicle’s speed without using the footbrake is called an endurance brake or retarder. It replaces some of the functions of friction-based brakes which are susceptible to brake fade on long downhill slopes. The retarder isn’t usually capable of bringing a vehicle to a standstill, so you have the normal friction-based service brakes for that. These systems mean your brake linings last longer.

Electromagnetic retarders work by applying a magnetic resistance to the prop shaft which, in turn, slows down the wheels. This allows the service brake to stay cool for optimum performance when required.

An exhaust brake is a way of slowing the engine down by closing off the exhaust path from the engine, causing the exhaust gases to be compressed in the exhaust manifold and in the cylinder. Effectively, the engine works backwards by creating negative torque. They’re most efficient when the engine is at high speed and in a low gear, such as when descending a long hill. Using the exhaust brakes can relieve the service brakes, preventing them from becoming hot and failing through over-use.

On very slippery roads take care with engine brakes as they will provide additional braking that could cause a skid.

Brake fade and drying your brakes

Your brakes’ effectiveness will be reduced if you have driven through deep water, such as a ford or flood. You must dry your brakes after driving through water by driving in a low gear with the footbrake lightly applied. Check what’s behind you before you do this. When you are doing it you will feel the brakes begin to bite again.

Brake fade happens when your brakes get too hot. The heat can boil the brake fluid meaning that bubbles form and it loses hydraulic pressure. The heat can also liquefy and vaporise the brake pads dramatically reducing their friction on the disks. Long downhill gradients are the main cause of brake fade.

Changing to a lower gear can help avoid brake fade, as can using a retarder or jake brake. Change down early, i.e. before you are on the slope.

Air brakes

Air brake systems usually have two lines. If your system has three lines, the third is an auxiliary (blue) line. Check with the manufacturer’s instructions what this can be used for. The red line is the emergency line. If there are only two connectors but three lines, don’t connect the auxiliary (blue) line.

You should never coast downhill because air brakes rely on an engine-driven compressor to replenish the air in the brake reservoir tanks. Coasting downhill and relying on the brakes to control your speed could result in a loss of sufficient air pressure to operate the brakes effectively, particularly if the compressor is worn.

In frosty weather a driver can drain the brake air storage tanks daily to prevent moisture freezing in them, which would cause a blockage that can prevent air pressure building up. Most modern vehicles have an automatic draining system.

If the brakes’ air pressure warning light comes on you should stop and seek help without delay as your brakes could be about to fail.

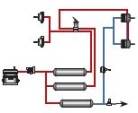

This diagram shows a simple air brake system:

If the brake pedal feels hard then the vacuum pump is not working. You should see a warning light or hear a buzzer.

If you are stationary and the air pressure warning light comes on, don’t release the parking brake because the service brakes might not stop you.

Anti-lock brakes

With anti-lock brakes a driver can push the footbrake firmly and continuously until the lorry or bus comes to a complete stop without risk of locking the wheels. Anti-lock brakes, or ABS, also allow the driver to maintain steering control while braking.

On a bus, the anti-lock braking system warning light should go out once speed increases above 6mph.

Jack-knifing

An articulated lorry is more likely to jack-knife when unladen, on a bend with the driver braking sharply. When a lorry jack-knifes the trailer tries to push the cab around. Jack-knifing can be caused by changing down to too low a gear while braking as the additional engine compression can cause the cab’s drive wheels to lock.

Here’s what it looks like inside the cab when a driver saves a lorry from jack-knifing on a snowy road.

Some lorries have jack-knife protection such as the one shown in this video.

Braking techniques

Progressive braking

Progressive braking puts the safety and comfort of the passengers is your first priority, and helps you get the most out of your vehicle as it reduces tyre wear and fuel consumption. Good forward planning and anticipation will enable you to avoid harsh braking and late, sharp steering. Badly driven vehicles cost more to run and maintain.

Cadence braking

Cadence braking will help you control a vehicle without anti-lock brakes. It’s a way of braking in slippery conditions and needs practice to perfect. It simulates ABS. The driver pumps the brakes to give some steering and braking on a slippery surface. First start by applying the brakes to the point where they lock up, then bring the brake pedal up until the wheels grip, then down again until the wheels lock again. Repeat the process.

On some surfaces, such as loose gravel, locking the wheels will stop you quicker than cadence braking. Cadence braking is less effective than threshold braking.

Threshold braking

Threshold braking requires practice and also for you to know very well how your vehicle performs under brakes. Threshold braking aims to keep tyre slip at an optimal amount by controlling brake pedal pressure. There will be a small amount of wheel lockup, and the driver modulates the brake pedal to maintain a balance between rotating wheels and locked wheels.

Braking emergencies

On a steep hill you will come across escape lanes which can be used if you experience brake failure. They will be indicated with a sign like this. They are a slip road with soft material at the end to stop runaway trucks.

If your brake pedal feels soft or goes to the floor either you are experiencing brake fade, or you have a serious loss of fluid from the hydraulic system. This must be checked and fixed by a qualified person. Do not drive it until this has been done.

Diff lock

When driving on muddy, slippery and loose surfaces you can switch on your diff (differential) lock to give you more grip. Engaging the diff-lock means that power is shared between the driven wheels. This reduces the chances of wheelspin. Remember to switch off the diff-lock as soon as you are on firm ground again, otherwise you could damage the transmission.

Seat belts

Seat belts hold you in place in a crash and under braking. If your lorry or bus is fitted with seat belts, you must wear them unless you have a valid medical exemption or the vehicle is being reversed.