What are refrigerated lorries and trailers (reefers)?

If you need to transport products that require a consistent temperature, a refrigerated truck or trailer is the solution. They have a chiller unit and thermostat which monitors the interior temperature and adjusts it to remain in a window of 3-5 degrees Celsius, regardless of the outside temperature.

There are strict regulations for transporting chilled produce to avoid contamination, decay and the growth of bacteria and mould that can cause illness. Perishable goods such as flowers and strawberries would not be possible to transport long distances without refrigeration.

Refrigerated units are most commonly rigid box body (hardside) trucks or semitrailers. It’s possible to get curtainside (tautliner) trailers with insulated curtains, but they are not some common, despite being much more convenient for loading from either side of the trailer as well as the rear.

The chiller unit is attached to the front of the trailer or box body, as can be seen in the photos above. It’s powered by diesel. In the case of a semitrailer, the driver would fill a separate tank which will last up to several days, depending on the outside temperature.

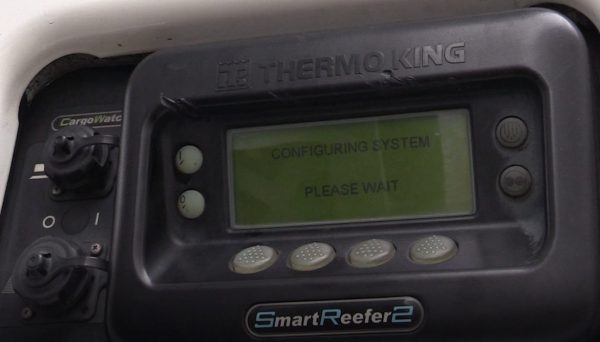

The driver sets the chiller temperature before getting to the pickup point. Some units can also be controlled remotely which allows a dedicated person to make sure that the units are all set to the correct temperature at the optimum time from the pickup point, meaning less wasted fuel. Drivers turning up with a trailer that is the wrong temperature may be turned away and asked to return several hours later, something that can play havoc with schedules and permitted work time.

Inside the trailer or lorry, the floor will allow for airflow by having grooves or vents.

The load should ideally be spread using the whole floor space, unless it can be constrained with bungs (see below). The maximum height of a stack should leave 80-100mm between it and the roof. All stacks should be the same height.

In dual temperature trailers, or where a partial load is being carried, large bungs can cordon off an area to make it more efficient and effective to maintain the temperature.

Reefers can be exposed to high humidity, so they need to be cleaned between loaded to prevent mould buildup and rust.

The chiller can ice up and may need to cycle its cooling to clear the ice.

Knowing how to check a refrigerated trailer is important so that you understand its operation, and can verify that the trailer is in good condition. For example, doors should seal correctly otherwise the chiller unit will use a lot more fuel.

- Understanding the National Standards for Riding Mopeds and Motorcycles

- Livestock Transport Rules UK: A Complete Guide to Animal Transportation Requirements

- The Role of Safety Advisers in Dangerous Goods Transport

- Sustainable Driving: Reducing Your Environmental Impact on the Road

- Developing Effective Lesson Plans for Driver Training

- UK Agricultural Vehicle Registration and Tax Relief

- Challenges of Transporting Radioactive Materials (Class 7)

- Exemptions and support for Clean Air Zone charges

- Navigating Legal Requirements: The UK Motorcycle Licensing Rules

- Safe Transportation of Agricultural Chemicals and Hazardous Materials

- Innovations in Vehicle Construction for ADR Compliance

- Motorcycle Recovery Operations: How to Recovery a Broken Down Motorbike

- Alternative Fuels in Agricultural Vehicles

- Carriage of Dangerous Solids in Bulk Containers

- Understanding Limited Quantity Exemptions in ADR